Labor Management System

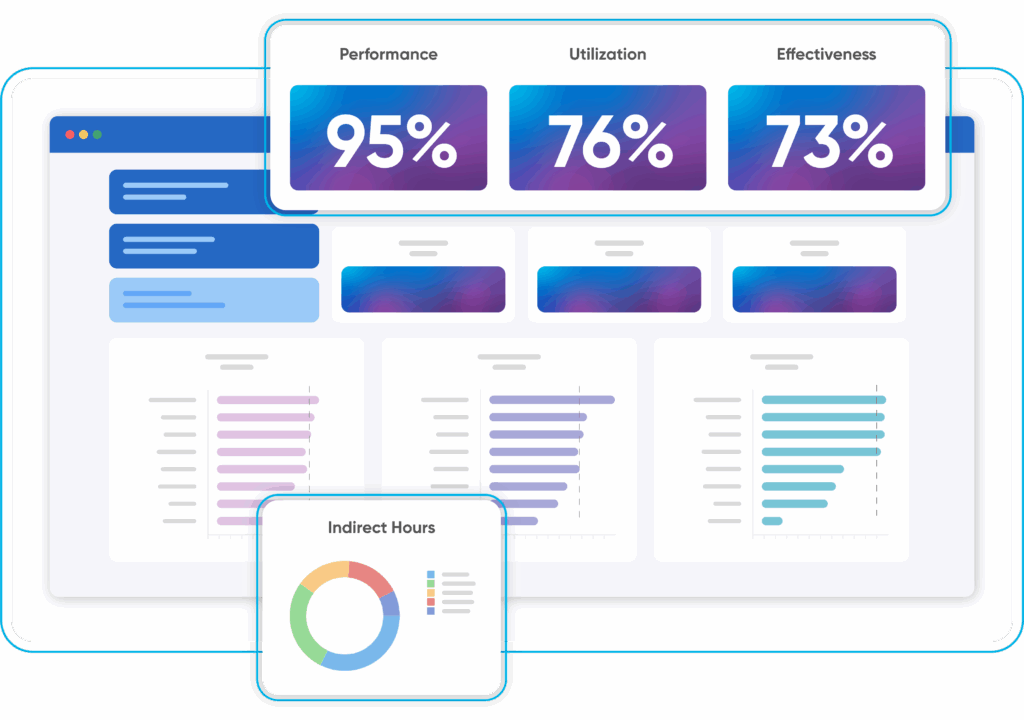

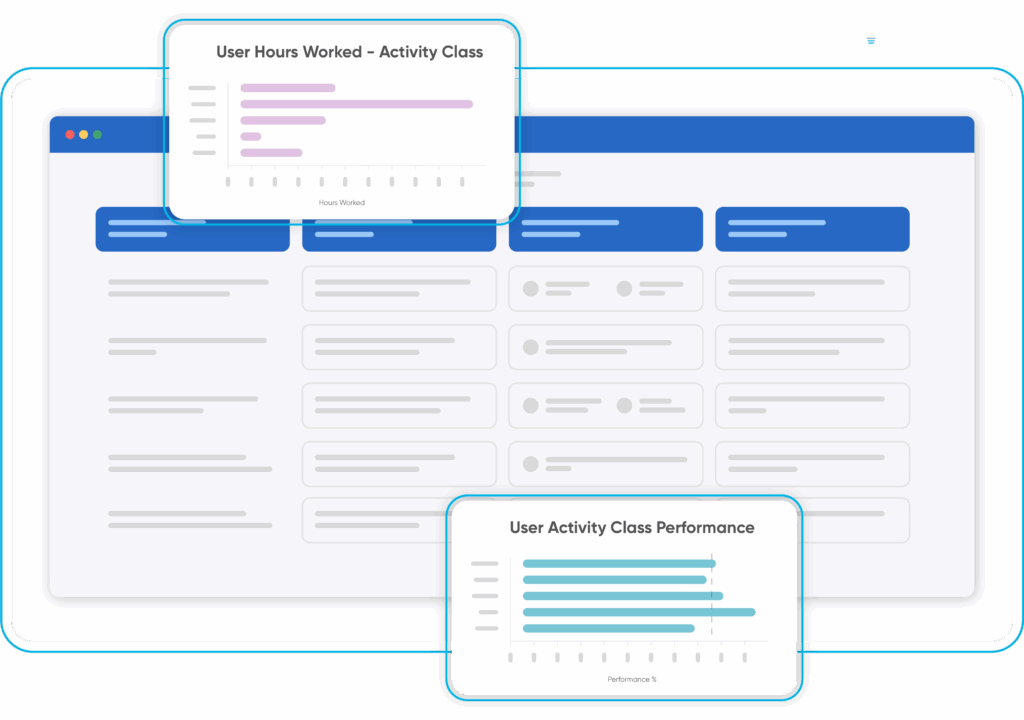

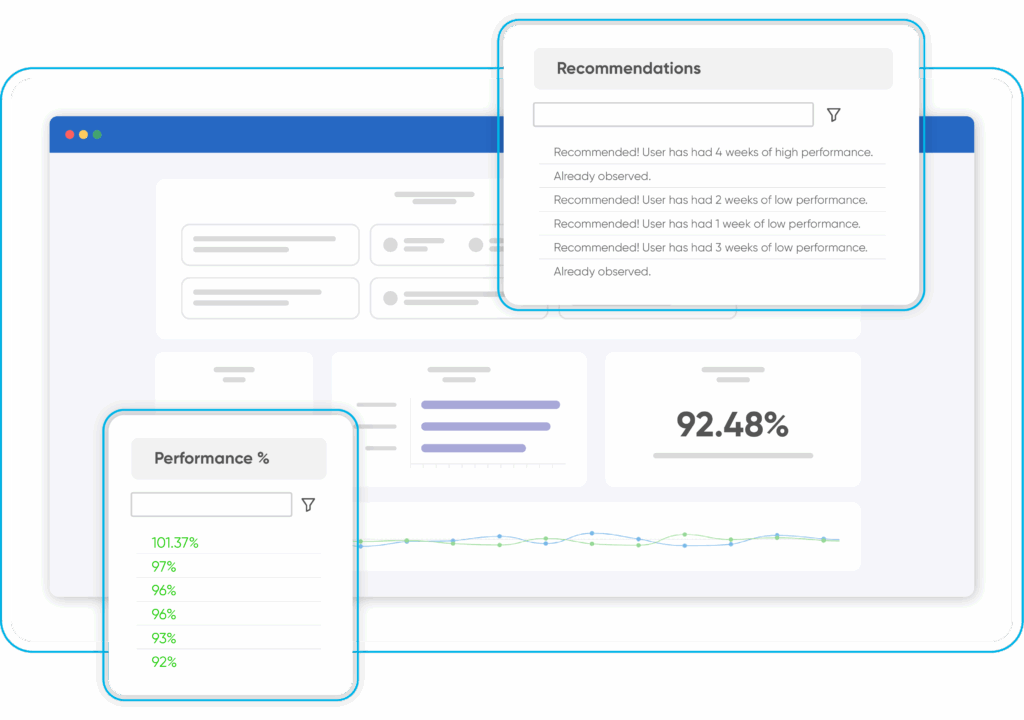

Know What’s Happening and What to Do About It

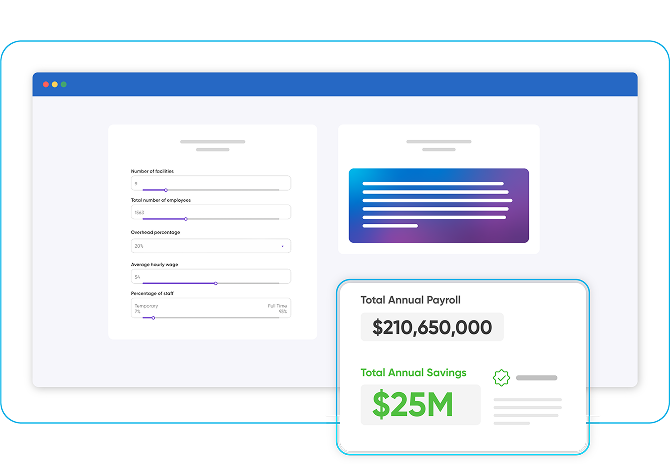

Rebus Labor Management System cuts through the noise so you can focus on what’s working, what’s not, and where to act next

Trusted by industry leaders to optimize over 500 warehouses everyday

Where most tools stop, we keep going

Here’s how our labor dashboards compare to traditional LMS tools and manual reports.

| What You Get | Rebus Labor | Other LMS Tools | Spreadsheets/ Dashboards |

|---|---|---|---|

| Track facility, shift, activity, and team productivity in real-time (<5 mins) | Yes | Typically previous day visibility. Real-time options often cost extra. | No. Requires manual update of data |

| Built-in support for common labor standards (ELS, UPH, RE) | Yes | Often supports a single standard; customization may require services. | No |

| Correlate labor productivity with orders, picks, receipts, inventory | Yes | No. Typically provides only labor KPIs. Limited operational context | Only what you build manually |

| Low total cost of ownership and strong return on investment | Yes | No. High upfront and maintenance costs. ROI depends on services. | No. Low cost to start, but expensive to scale or maintain. |

| Multiple integration methods (API, file, database) | Yes | Partial. Usually API only; file support varies; DB access rare. | No. Manual uploads and exports only. |

| AI-powered labor forecasting | Yes | No. Mostly historical or trend-based reporting. | No. Static reports based on past data. |

Get a Unified View, Beyond Just Labor

Rebus connects labor performance with real-time inventory, process analytics, and 3PL billing, giving you one platform to see, manage, and improve your warehouse.

Frequently Asked Questions

- What is a Labor Management System (LMS) ?

A labor management system (LMS) is warehouse software that tracks, measures, and improves workforce performance. It provides visibility into labor productivity, helps manage tasks efficiently, and ensures resources are used effectively to meet operational goals.

- How does a Labor Management System reduce costs?

An LMS lowers costs by improving workforce productivity, reducing overtime, and eliminating inefficiencies. It enables better labor forecasting, accurate scheduling, and real-time performance tracking — helping warehouses do more with fewer resources.

- How quickly can you see results with an LMS?

Most organizations see ROI within months through higher throughput, lower labor costs, and better workforce utilization.

- Can a labor management system (LMS) integrate with warehouse management systems (WMS)?

Yes. Most LMS platforms, including Rebus, integrate seamlessly with WMS, ERP, and time-tracking tools for unified labor visibility.

- What’s the difference between a labor management system and a workforce management system?

A labor management system focuses on warehouse productivity and task performance, while workforce management covers broader HR functions like attendance and payroll.

- How long does it take to implement a Labor Management System?

The implementation of a Labor Management System can vary, but most businesses go live with Rebus in 8–12 weeks. Because Rebus is cloud-based and lightweight, it avoids the long, complex deployments that traditional labor management systems often require.

- What kind of ROI can we expect, and how quickly?

Most companies see ROI from a Labor Management System within 3–6 months. The Rebus Labor Management System drives ROI by improving workforce productivity, reducing overtime, optimizing labor planning, and identifying bottlenecks that slow down operations. Many organizations start seeing measurable improvements within the first few weeks of use.

- What labor KPIs does a Labor Management System track?

The Rebus Labor Management System tracks essential labor KPIs such as:

- Employee productivity

- Task completion time

- Labor utilization

- Direct vs. indirect labor

- Standard vs. actual performance

- Attendance, adherence, and shift compliance

These KPIs help warehouse teams understand performance and take action to improve throughput.

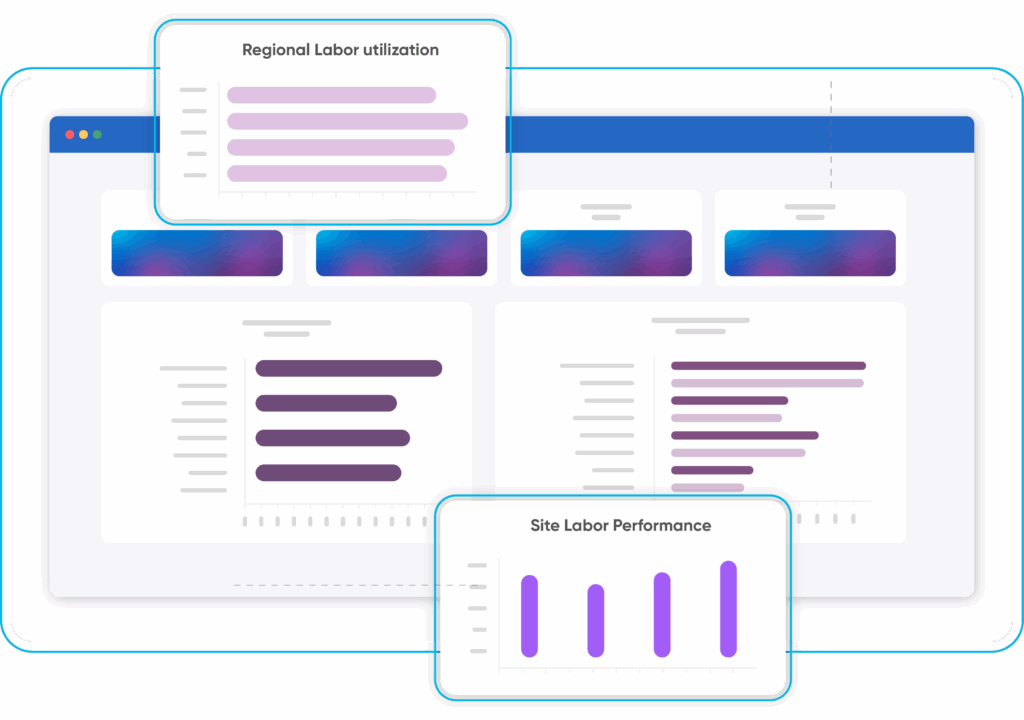

- Can a Labor Management System scale across multiple warehouses or regions?

Yes. The Rebus Labor Management System is designed to scale across multiple warehouses, distribution centers, and regions. As a cloud-based platform, it delivers consistent performance metrics across every site and gives leadership a unified view of labor performance.

- How accurate and real-time is the data?

The Rebus Labor Management System provides real-time, highly accurate data directly from your operational systems. Supervisors can see productivity changes as they happen, helping them quickly address delays, balance workload, and improve daily workflow.

- Is our operational data secure?

Yes. Data security is a core part of the platform. The Rebus Labor Management System is SOC 2 compliant, uses strong encryption, secure cloud infrastructure, user-access controls, and continuous monitoring. This ensures all operational and employee data remains fully protected.